Whole Tire Shredder

Qingdao Shun Cheong Machinery Co., Ltd is the professional manufacturer of various vulcanizing press and press machine. Our company has passed ISO9001:2008 Quality Management System Certification and our products have qualified with Sweden SGS Certificate, UKS Certificate and CE Certificate.

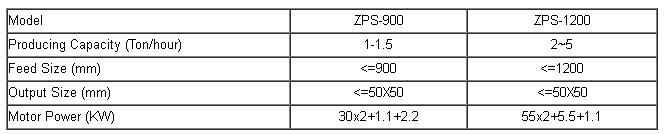

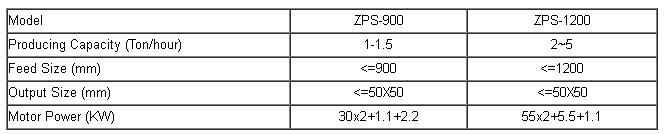

1. The whole tire shredder broken steel radial tire and fiber bias tire into a the glue block of about 50 * 50mm equipment, suitable for crushing to remove the bead and in accordance with the feed specifications waste tire.

Powerful whole tire shredder capacity, low energy consumption, advanced tire crushing processing equipment, advanced technology, without manual operation.

2. Automatic rubber powder production line is suitable for dealing with the various nylon cord tires, steel tires, large-scale projects such as fetal crushing processing waste rubber products, rubber powder and nylon line, wire full separation, production of rubber powder diameter 1.7mm ~ 0.12mm between. The high degree of automation of the production line, requiring fewer workers, wearing parts can be reused, the high safety factor of the whole production line.

3. The whole tire shredder main motor, reducer, chassis, tool, mesh circle, transmission mechanism, rack, etc. The main features are as follows:

3.1 Crushing cavity using a split structure, easy installation and maintenance, equipment, compact structure.

3.2 Cutter head edge made of the special selection carbide material, and after a follow-up special high hardness, high wear processing, in a short period of time, rapid replacement of the wear part of the cutter head, cutter head wear, difficult to replace, difficult repair, the problem of high costs. Long service life, high efficiency, advanced technology, and easy to replace.

3.3 With high endurance, high wear-resistant, energy-saving, low-noise, high torque Hardened reducer, higher security.

3.4 Rotary sieves for steel wire grid structure, blanking area, conducive to the classification of qualified plastic block to avoid a qualified plastic block in the crushing cavity repeated broken and reduce production.

3.5 Oversize tires simply divided equally able to achieve the desired crushing effect.