The new EPDM colored rubber particles have the advantages of health, non-toxicity, safety, environmental protection and durability etc., and are widely used in sports venues such as plastic track, basketball court, tennis court, gymnasium, community leisure square, kindergarten non-slip area etc.

Our company has been participating in the EPDM granules industry since 2015, and has project cooperation with Qingdao University of Science and Technology. So far, our company has provided EPDM granules production line to many domestic companies and participated in EPDM granules production processes .

Compared with traditional lines, this production line mainly has the advantages of less labor intensity, high productivity and high degree of automation.

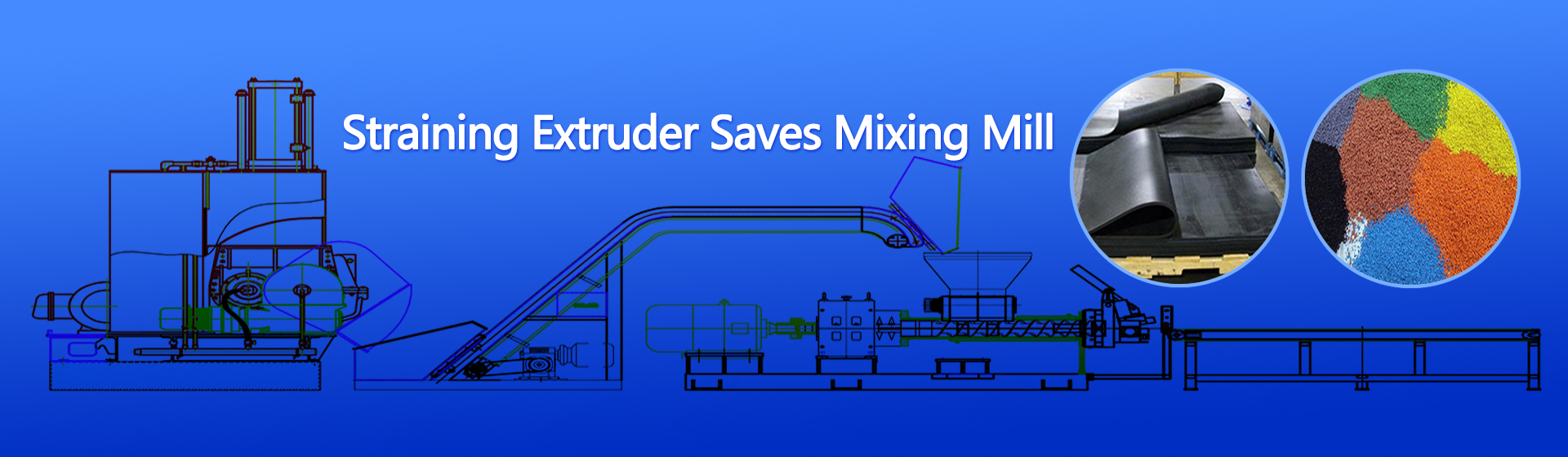

The rubber compound mixed by the internal mixer is directly fed into the twin rotors feeding mechanism of the extruder and extruding different shapes by screw pushing and conveying effect.

The feeding structure of the extruder adopts a twin rotors forced feeding, which can directly feed the rubber ball from the mixer into the extruder. Compared with the old process, it saves rubber mixing mill and labor intensity, greatly reduced production cost. Moreover, Good feeding effect, strong extrusion ability, which greatly reduces the work intensity of the workers and lower investment cost.

The head of the extruder adopts hydraulic locking, hydraulic opening and closing of the upper and lower heads, which is convenient to change the rubber color and clean the rubber inside the head. This kind of head has good cooling effect, the rubber won’t be pre-vulcanized, and with higher production efficiency compared with same model.

Double-arm fed rubber strainer

replace the mixing mill

It is widely used in cable industry, reclaimed rubber industry, inner tube industry and rubber hose industry etc rubber profiles manufacturing.

Compared to traditional technology, through replace the function of rubber mixing mill during rubber compound mixing, save labors and greatly decreased production cost.

Model | XJL-150 | XJL-200 | XJL-250 |

Screw diameter(mm) | 150 | 200 | 250 |

Main motor(Kw) | 45 | 75 | 110 |